The Crucial Importance of Testing Products to DO-160G Standards

Biggleswade, UK — 1st September 2023 —

Author Nathan Herbert

In the fast-paced world of aviation, the safety and reliability of products and equipment are of paramount importance. Whether it’s avionics, communication systems, or electronic components, ensuring that they can withstand the harsh environmental conditions encountered during their operational lifetime is critical. This is where DO-160G testing comes into play. In this article, we will explore the significance of testing products to DO-160G standards and why it is a vital aspect of the aviation industry.

Meeting Regulatory Requirements

One of the primary reasons for testing products to DO-160G standards is to meet the stringent regulatory requirements set by aviation authorities. Regulatory bodies, such as the Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA), mandate compliance with DO-160G for the certification of airborne equipment. By adhering to these standards, manufacturers ensure that their products are airworthy and meet the highest safety standards.

Ensuring Reliability in Extreme Conditions

Aircraft operate in a diverse range of environmental conditions, from high-altitude flights to extreme temperature variations. DO-160G testing simulates these conditions to evaluate how well the product can endure them. By subjecting products to tests like temperature and altitude, humidity, vibration, and shock, manufacturers can identify potential weaknesses and make necessary design improvements. This ensures that products maintain peak performance throughout their operational life, reducing the likelihood of in-flight failures and improving overall reliability.

Enhancing Aviation Safety

The safety of passengers, crew, and cargo is the top priority in the aviation industry. Testing products to DO-160G standards plays a pivotal role in enhancing aviation safety. By certifying that airborne equipment can withstand lightning strikes, radio frequency interference, and electrostatic discharges, the risk of critical system failures due to environmental factors is significantly reduced. Consequently, this minimizes the chances of incidents or accidents that could jeopardize the safety of flights.

Minimizing Downtime and Maintenance Costs

Products that pass DO-160G testing with flying colors exhibit a higher level of robustness and durability. By identifying potential weaknesses during testing, manufacturers can make necessary improvements before the products are deployed. As a result, airlines and aircraft operators experience reduced downtime and maintenance costs associated with repairing or replacing faulty equipment. This also leads to improved operational efficiency and lower overall operating expenses for the airlines.

Building Trust and Reputation

In the competitive aviation market, trust and reputation are crucial. Manufacturers that consistently test their products to DO-160G standards demonstrate their commitment to quality and safety. Such adherence to rigorous testing and compliance with industry standards builds trust among airlines, aircraft operators, and passengers, enhancing the manufacturer’s reputation in the market. A strong reputation can lead to increased sales, new partnerships, and continued growth in the aviation industry.

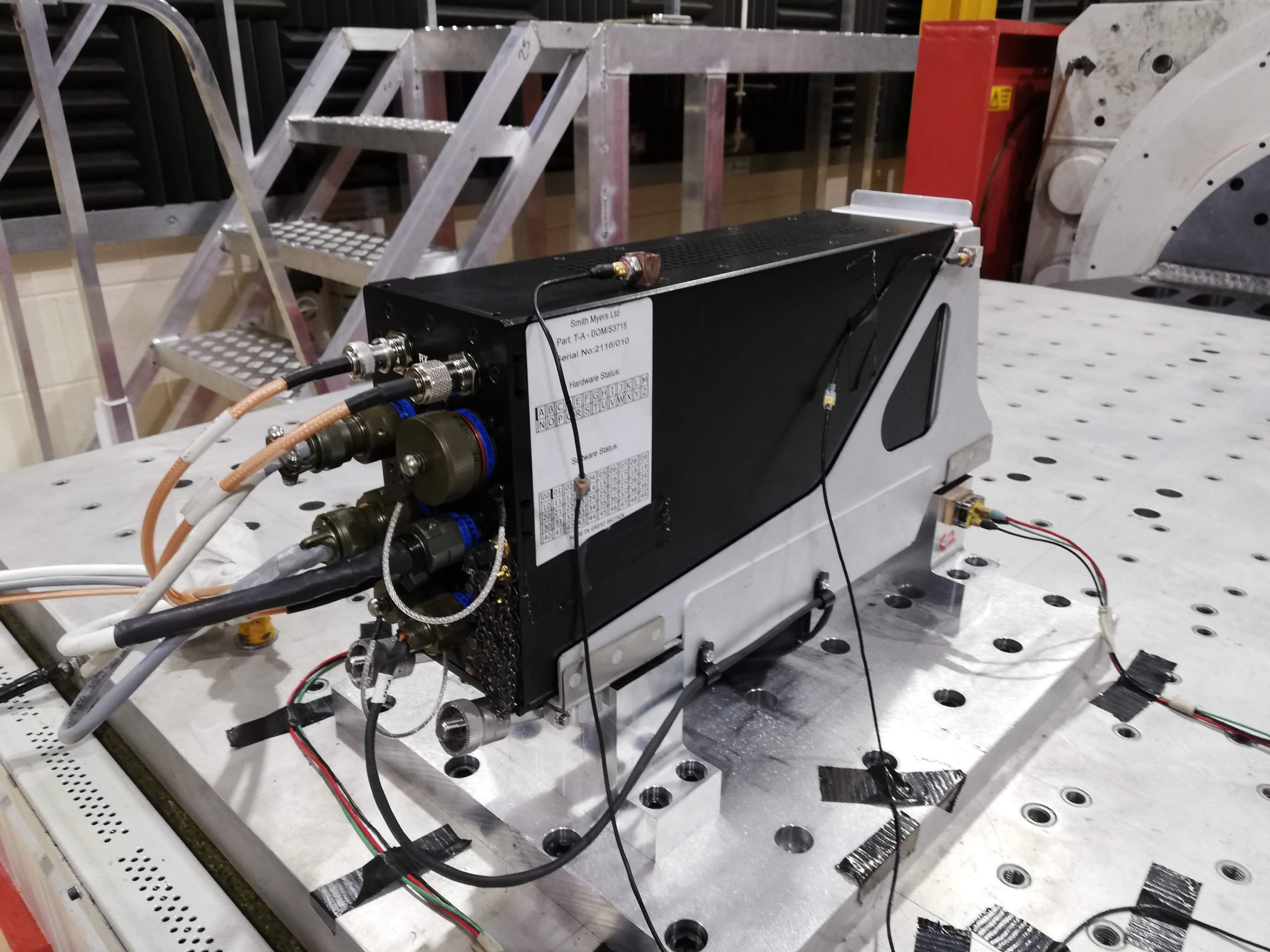

In conclusion, testing products to DO-160G standards is an essential and non-negotiable aspect of the aviation industry. It ensures that airborne equipment is capable of withstanding the diverse and demanding environmental conditions experienced during flight. By adhering to these rigorous testing procedures, Smith Myers can meet regulatory requirements, enhance aviation safety, and minimize maintenance costs. Moreover, robust products that pass DO-160G testing contribute to building trust and reputation, propelling Smith Myers to the forefront of the competitive aviation market. Ultimately, investing in DO-160G testing is not only a regulatory obligation but a commitment to delivering safe, reliable, and high-quality products that keep the skies safe for everyone.